M12 connector M8M5M23 Power Battery Box Hight Low

+86-15817275200

+86-15817275200

+86-15817275200

+86-15817275200

Company News&Blog

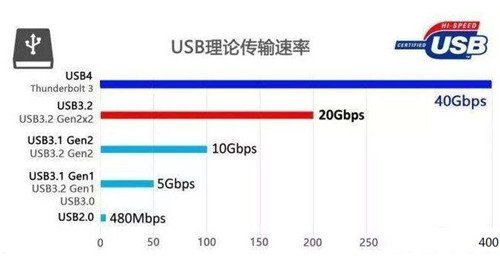

Your current location:Home - Blog&News - Company News&BlogUsb-if officially authorized ul to become USB4 cable and USB4 pd3.0 e-marker silicon certification testing laboratory on September 9, 2020.

In order to meet the requirements of USB4 gen3 characteristics, we should focus on: 1. Design and production process of bare wire; 2. Assembly and processing technology of wire; how the design of wire rod can meet the requirements of USB4 gen3 characteristics, we should refer to the following: attenuation characteristics, related design: conductor design process loss. Crosstalk, building design: shielding material design, arrangement. Return loss, core design, insulation material dielectric, shielding material design. Differential signal to common mode signal, build design: Design of all process parameters. Com threshold: conductor design, process loss, shielding material design, alignment.

Where com threshold If you want to know all the complete test items, please refer to the relevant articles: USB4 cable design, test and failure analysis; and for the related process and construction parameters of wire rod, you can refer to: wire extension, single bare copper, conductor diameter and annealing stability, tin / silver, bare copper tin plating, silver, plating thickness and uniformity. Bundle stranding, tin plating, silver copper stranding, empty full shaft conductor diameter and roundness, core pressing, core wire insulation extrusion, die fixture design and extrusion temperature setting. Winding, winding and wrapping tape, winding tension, twist pitch, overlap ratio stability. Core stranding, wire forming, pay off tension and stability of stranding distance. Knitting, shielding, braiding tension and take-up empty full axis tension, forming charge, external extrusion, die fixture design and ejection temperature setting.

About USB4 cable assembly requirements

Test item: E-MARK test of b-1-1 chip: the chip on USB4 cable assembly shall meet the requirements of USB4 e-marker4.13.5 in USB type-C function test specification. B-1-4 wire flexibility requirements: from the original swing 100 times to 500 times, this part can be designed from the wire or conductor pitch, material or extrusion parameters to overcome this problem. B-8 USB4 gen3 characteristic requirements: insertion loss fit at Nyquist frequencies ilfitatnq attenuation, integrated crosstalk on TX / RX pairs inext and ifext crosstalk.